Since the rapid popularization of consumer electronic products in the 1990s, although they have brought more convenience to human life, they have also caused problems such as heavy metal pollution caused by discarded electrical appliances, posing in...

Since the rapid popularization of consumer electronic products in the 1990s, although they have brought more convenience to human life, they have also caused problems such as heavy metal pollution caused by discarded electrical appliances, posing increasingly serious risks to human health and the environment.

The European Union, which has always paid attention to environmental protection and health issues, implemented the RoHS Directive (Restriction of Hazardous Substances Directive) in 2003 in order to prevent the release of harmful substances such as lead, mercury, and cadmium during the manufacturing and recycling process. It restricted the use of materials in electronic and electrical products from the source, and also forced the global supply chain to transform towards "green manufacturing" and "material substitution".

Considering that it is difficult to find raw materials that can replace lead in the short term for passive components such as resistors and capacitors in electronic ceramic components, the EU has also specially formulated RoHS 7(c)-I exemption clauses to allow some electronic components to still contain trace amounts of lead, allowing manufacturers to maintain existing designs in existing products. However, this exemption is temporary. Although it has been extended to June 2027, there is still a huge risk of revocation and uncertainty. Once the EU decides not to extend or cancel the exemption at any time, it will have a huge impact on the manufacturing industry and system integrators.

As the world's leading digital storage brand, Apacer Technology, in addition to actively investing in technology research and development and optimizing production capabilities, also prioritizes sustainable development. It will launch "Fully Lead-free" DDR5 fully lead-free memory in 2024. At the same time, it will also continue to release the solid state drive "PV250-M280" that conforms to the fully lead-free concept this year. It uses technological innovation and green manufacturing processes to deploy a green supply chain in advance, becoming one of the few brands in Taiwan to complete the mass production of fully lead-free products, demonstrating the strength of a global sustainable supply chain.

▲ Huang Zijia, product project manager of Apacer Technology

Huang Zijia, product project manager of Apacer Technology, pointed out that in the past few years, the EU only announced that the exemption clause would be extended for two years 2– 3 months before RoHS 7(c)-I was about to expire. This move is bound to bring great psychological pressure to the manufacturing industry and system integrators. However, for electronic component manufacturers, complying with the RoHS Directive is not only a compliance challenge, but also means the need to restructure the supply chain and re-verify products. Once the EU announces the cancellation of the RoHS 7(c)-I exemption clause, if manufacturers cannot switch materials and processes in time, products may not be sold to the European market.

In fact, large brand customers in the EU have already expressed their desire to purchase lead-free products, and governments around the world have responded to environmental protection policies. To this end, Apacer Technology has incorporated the concept of fully lead-free design into the core of product development and supply chain strategies, making the company the only brand in the market that can provide fully lead-free SSDs and memories.

Achieve sustainable competitiveness based on compliance with regulationsApacer Technology's "Fully Lead-free" series of products covers three major aspects, namely "material innovation", "process optimization" and "strict verification". It hopes to use a multi-pronged approach to respond to the challenges of RoHS 7(c)-I that may be terminated at any time, and at the same time demonstrate the company's commitment to sustainable development. After nearly a year of R&D and testing, Apacer Technology finally successfully completed the introduction of a full range of lead-free components, becoming one of the first leading digital storage solution brands in Taiwan with mass production capabilities for Fully Lead-free memory, solid-state drives and other products.

▲ Image source: Apacer Technology

Apacer Technology has always maintained a close cooperative relationship with upstream passive component suppliers. The original factory uses metals such as tin, silver or copper to replace lead, which meets the requirements of more stringent environmental regulations. It no longer needs to rely on lead exemption clauses, and is ahead of schedule to respond to the future of regulations and policies. In addition, traditional solid carbon crystal resistors can also be replaced by single cermet resistors to reduce installation costs and simplify design.

Huang Zijia said that in terms of process optimization, Apacer Technology has also introduced low-temperature welding technology and the underfill process into the production line. Through dual optimization of materials and processes, the structural stability of the product has been significantly improved. Among them, low-temperature welding technology can reduce the welding temperature by about 30% and reduce overall energy consumption by 15 to 20%. In addition to helping to reduce carbon emissions, it can also improve product yield and process stability. As for the underfill process, it can strengthen the adhesion between the chip and the PCB and effectively prevent the chip from falling off due to high temperature or vibration. It is especially suitable for high-reliability application scenarios such as automotive, industrial control and edge equipment.

In order to ensure the reliability of all lead-free products, Apacer Technology conducts a number of high-standard tests on its products, including high-temperature aging, thermal cycling, hot and humid environment and vibration tests, to ensure that all lead-free products meet high standards in terms of stability, lifespan and stress resistance. It is worth mentioning that Apacer Technology’s all lead-free products have passed third-party SGS certification to ensure that the quality meets international standards while achieving goals such as energy saving and carbon reduction, product stability and extended life.

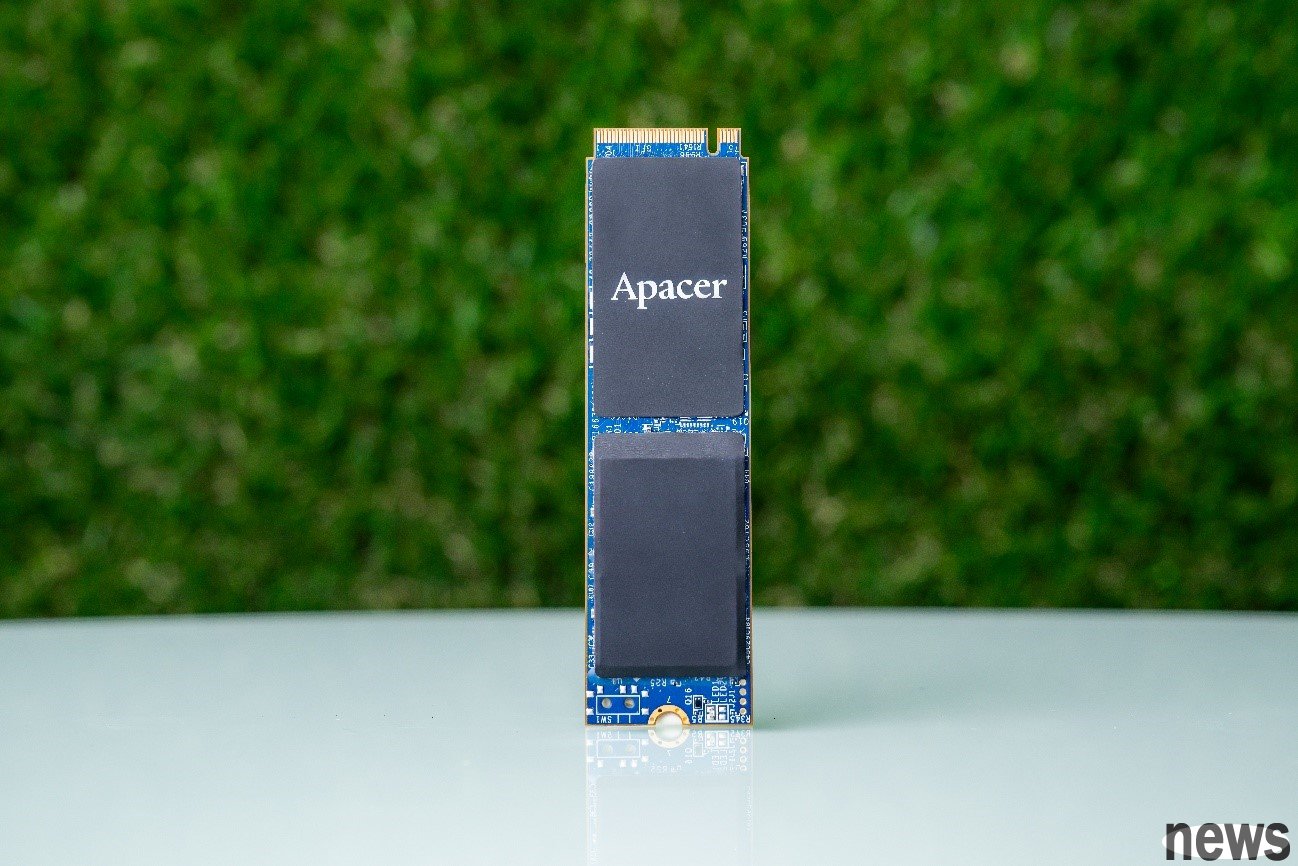

Comply with mainstream specifications and meet global enterprise application needsApacer Technology’s full range of industrial DDR5 memory modules have all introduced lead-free resistors to meet the introduction needs of enterprises in various application fields. PV250-M280 is Apacer Technology's first fully lead-free SSD. It adopts the current mainstream PCIe Gen 4×4 interface and NVMe 2.0 specification, providing a maximum storage capacity of 3.84TB. In terms of data reading and writing speed, the continuous reading speed can reach 3,675 MB/s and the writing speed is 3,215MB/s, which can meet the needs of high-performance applications such as industrial Internet of Things and edge computing..

In terms of product reliability, Apacer PV250-M280 complies with stringent industrial-grade specifications, has an extremely wide temperature range, and can operate stably in extreme environments from -40°C to 85°C. The mean time between failures (MTBF) exceeds 3 million hours, ensuring long-term stability. When pursuing performance, Apacer Technology is also committed to reducing energy consumption. PV250-M280 is equipped with the self-developed CoreEnergy energy-saving mechanism, which can automatically switch power modes according to changes in ambient temperature and workload, effectively saving up to 67% of power consumption, turning green benefits into considerable energy savings.

To ensure data integrity in harsh environments, PV250-M280 adopts an Underfill structural reinforcement design, which makes it have excellent shock resistance and thermal shock resistance. In terms of data security, the product also integrates the LDPC ECC error correction mechanism, End-to-End Data Protection, and the industry's high-standard AES 256-bit encryption technology to provide comprehensive protection for critical data.

Huang Zijia pointed out that in the past, brand owners or system integrators focused on product specifications. We find that now they have gradually shifted to whether they can provide fully lead-free products, especially in the European market. Taking market demand into consideration, we are currently launching fully lead-free solid-state drives with mainstream specifications. If our partners require products with other specifications, we are confident that we can provide them within 2-3 months. This is a competitive advantage that other companies will find difficult to catch up with.

With the advent of fully lead-free memories and solid-state drives, Apacer Technology has demonstrated its response to the wave of sustainability with technological innovation. In the future, it will continue to pay attention to market trends and customer needs, and gain a dominant position in the global market through strategies such as lead-free products across the board and international sustainability certification.

More information on lead-free SSD: Click here More information on fully lead-free DRAM: Click here Contact us: click here