The Trump administration has pushed back on chip manufacturing. Su Zifeng, executive director of Ultramicro, recently talked about strengthening the construction of a semiconductor supply chain in the United States, "but it takes a long time&qu...

The Trump administration has pushed back on chip manufacturing. Su Zifeng, executive director of Ultramicro, recently talked about strengthening the construction of a semiconductor supply chain in the United States, "but it takes a long time"; the industry analyzes the effectiveness of settlements as a major test, and the conflicts in the distribution of interests of Americans and states constitute challenges; the subsequent production process of chip products is still difficult to complete in the United States.

Howard Lutnick, the U.S. Minister of Commerce, recently mentioned the "55-5" chip manufacturing in Taiwan, which attracted attention. The Donald Trump administration has pushed back the manufacturing process. Huang Rensheng, executive director of chip manufacturers NVIDIA, Ultramicro (AMD), and Su Zifeng have repeatedly publicly stated that they support diversified land to strengthen supply chains.

Su Zifeng attended the China-US Semiconductor Association (CASPA) Annual Dinner in Silicon Valley on September 27. He was asked about the opportunity and challenge of building a semiconductor manufacturing ecosystem in the United States. He pointed out that it is very important to distribute production points in different regions. Many semiconductor companies are working hard to bring more manufacturing to the United States and other parts of the world. Industry should support this approach.

She added that Taiwan is extremely outstanding in efficient production and providing advanced technology performance. "Our cooperation with Taiwan Electric may be our most important partner relationship", and semiconductors are of great importance and must ensure diversification of supply chains.

She also pointed out that it takes a long time, great effort, and a joint cooperation that supplies all links.

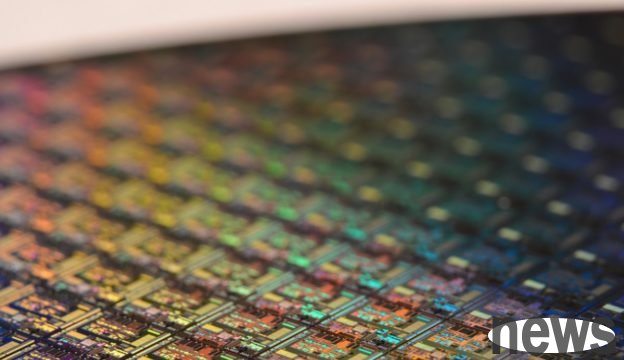

▲ Ultramicro operation is long and plump. (Source: Technology News)

The US government policy continues to ferment in Silicon Valley, and the semiconductor community builds consensus and faces challenges through dialogue tests.

Huang Hansen, chief scientist of Taiwan Electric and professor of the Department of Electrical Engineering at Stanford University, was asked about similar problems at a seminar. He said as a scholar that Taiwan and the United States have different challenges in the development of semiconductors; in Taiwan, the increasing demand but the gradual shortage of talents is a major problem, and Taiwan Electric has attracted almost all available doctoral talents in Taiwan.

As for the United States, Huang Hansen pointed out that the biggest difficulty in US semiconductor manufacturing is the "district" where the population of 50 states is scattered everywhere, and many successful advanced manufacturing industries in the world have cluster effects. The entire supply chain ecosystem and the entire basic facilities are geographically close to each other to support each other.

Huanghansen Example: A crystal factory that transports 24 hours a day, 7 days a week, once the equipment fails, the supplier's engineer must be around to help solve the problem, and it is unlikely that the supplier will send someone to deal with it.

He analyzed that this settlement effect still needs to be developed in the United States, and politically, it is very difficult to gather all resources in the same place. "These are the key challenges that the United States needs to solve."

He also said that the settlement takes time to form, and it cannot be done overnight; for example, the car manufacturing industry in South Carolina, southern United States is a successful example. Japanese and German companies continued to establish car factories locally and achieved results in creating settlement effects, but that was gradually realized after about 30 years, "we must be very patient."

An unknown semiconductor industry insider analyzed to the Central News Agency that the US government's actions have indeed helped chip manufacturing return to the United States. Taiwanese companies have expanded their production capacity and created related supply chains in the United States. At the same time, it has been a progressive approach to continue to diversify foreign risks. However, companies with lower gross profit in the later stage of the supply chain come to the United States to face challenges such as cost and profit.

He said that after NTF production, the subsequent process may take at least one month or more after completion. The United States lacks companies that can take over those sectors. Even if the wafer factory is built, it may still have to be sent back to Asia for the subsequent process after a certain stage in order to make the final product problem, and there are still many tests on costs and processes.